Under tile roofing

Sustainability

With the implementation of cutting-edge technologies and innovation in the manufacture of its under tile roofing boards, Onduline reduces the carbon footprint with low primary energy consumption. The lightness of this material allows for more efficient transport, thus reducing CO2 emissions, and its composition allows the recycling of a high amount of material per year. Recent certificates demonstrate the company’s ongoing concern with regard to the issue of environmental quality.

Features

Onduline under tile roofing boards are lightweight, making installation easier and reducing labor costs. They are impervious to water (30 year warranty). Constant ventilation between all roof elements increases their durability.

Applications

Onduline under tile roofing boards easily adapt to the rehabilitation of sloping ceramic tile roofs. In rehabilitation, its use allows to reduce changes in the configuration of the covers to the minimum possible, reducing costs.

ONDULINE ENERGY

Sustainability

Onduline Energy is a new insulation solution from Onduline. With this 100% natural material, Onduline completes its coverage offer with a solution that guarantees greater thermal comfort, noise reduction and, consequently, greater sustainability.

Features

Onduline Energy is composed of high density bi-layer rock wool (100/180 kg / m3), which gives it great qualities in terms of thermal and acoustic insulation and fire resistance.

Applications

Onduline Energy is especially indicated to be applied to roofs but it can, however, have other more common uses as general rock wool.

ONDUTHERM WALL

Sustainability

ONDUTHERM® WALL is a construction system that allows insulation from the inside, whenever it is not possible to carry out thermal insulation from the outside or when it is important to preserve the heritage, maintaining the original facade.

This system also makes it possible to create partition walls, with minimal or even non-existent use of metallic profiles, reducing thermal bridges and facilitating the installation of the solution.

Features

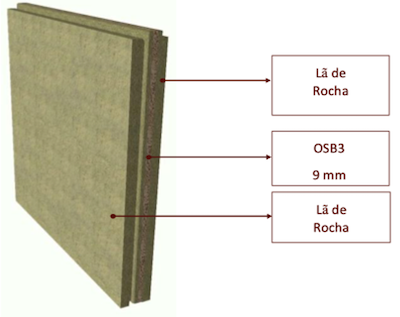

This system is formed by male-female blocks on the four sides, composed of rock wool thermal insulation on the two outer sides and an OSB layer at its core. The system can be coated with a finish of choice (for mechanically fixed coatings).

Applications

Interior wall cladding with insulation.